Recent technology guides

Understanding 3D printing technologies

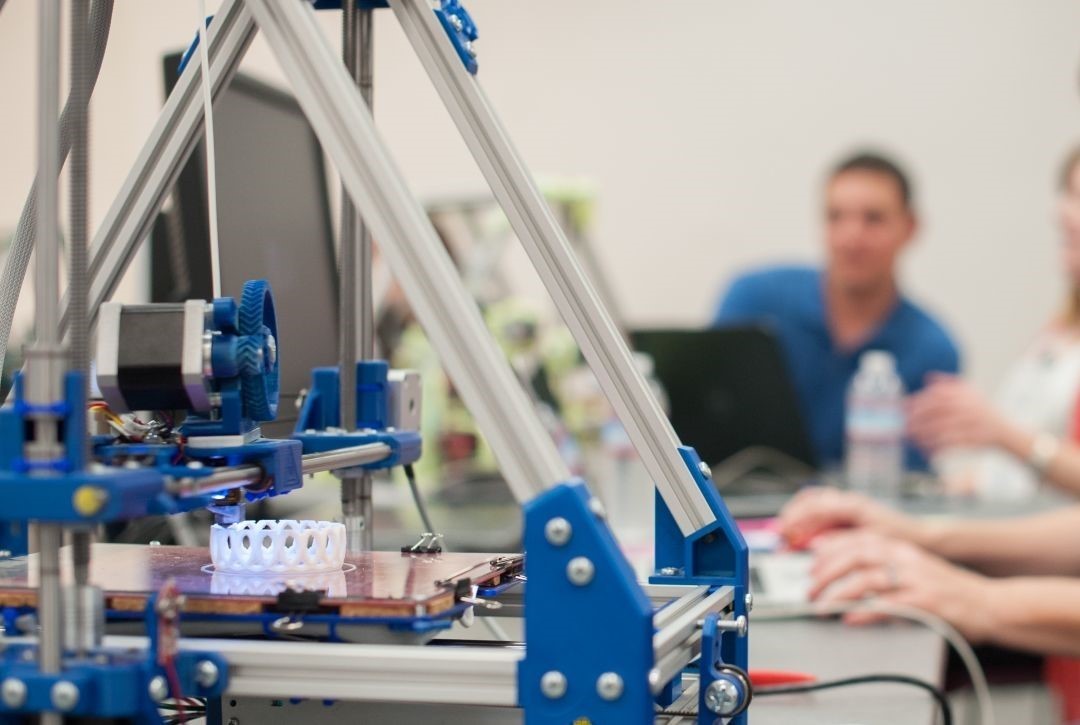

3D printing is the name used for the process of manufacturing various objects by stacking layers of materials according to a 3D digital model that is used as a reference. This process makes it easy for people like you and me to create complex designs from the comfort of our homes. Here are a few examples.

Until recently, you needed to go to a factory to build custom plastic-made objects, for example. And if you wanted to get a good price, you had to print at least a few thousands of identical objects! Fortunately, 3D printers are inexpensive; some of them will only set you back $100 or so, and they are quite easy to set up and use. Unlike there industrial counterparts, they won't fill an entire room; most of them have the size of a laser printer, to give you an idea.

People use additive manufacturing, the technical name for the process behind 3D printing, to create all sorts of objects: toys, decorations, phone cases, and so on.

3D printers are able to reproduce the information that is stored inside those 3D models in real life. You can use applications such as SketchUp to build your model, or simply utilize one of the tens of thousands of models that can be downloaded for free using the Internet.

Once that the model is loaded into your printer's application, you can set the size of the end product, adjust its quality, choose to print it on a platform (or not), and so on. Then, you will need to choose the desired material. Often, 3D printers are used to create objects made out of plastic, but you can choose other filaments (the "ink" for your 3D printer) which contain a mix of plastic and metal, wood, and so on.

It's time to hit the "Print" button! As you know, a standard inkjet printer creates a document by depositing tiny drops of ink on paper. Similarly, 3D printers create objects by depositing tiny bits of material on top of each other. Trust me, it's quite tempting to waste a few hours of your time watching how your beautiful model is slowly replicated in 3D. Actually, the printing process will only last about an hour if you're designing a simple object.

Additive printing is a new technology, I know. So, I understand why some people may feel a bit intimidated about it. Still, if you dare to invest a few hundreds of dollars into a good 3D printer, I guarantee that you will get to design and build lots of useful and funny things.

You could build your kids their preferred toys, for example. If you aren't married yet, you can design a gorgeous looking wedding ring in only a few minutes. Or, you could print a great looking watch, rather than purchase it. You could even replace that broken doorknob with a new, modern version of it. Designers utilize 3D printers to create quick prototypes for their next-generation shoes, furniture, jewelry, etc.

Basically, if you can think of it, you can probably 3D print it! This is made possible by the vast array of materials that are available for your projects: Alumide (nylon and aluminum particles), ABS (think Lego bricks), PET (the material used for water bottles), PETG (PET combined with glycol), FDM (conductive materials), high-impact polystyrene, polyamide, and many more.